YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 04.02.2021 Category: science/research/innovation

Not only water but also valuable raw materials can be recovered from sewage, and these are then used in areas such as agriculture or medicine. Research is underway at WUST in collaboration with MPWiK (the municipal water management company) to develop a special technology for the Janówek Sewage Treatment Plant in Wrocław.

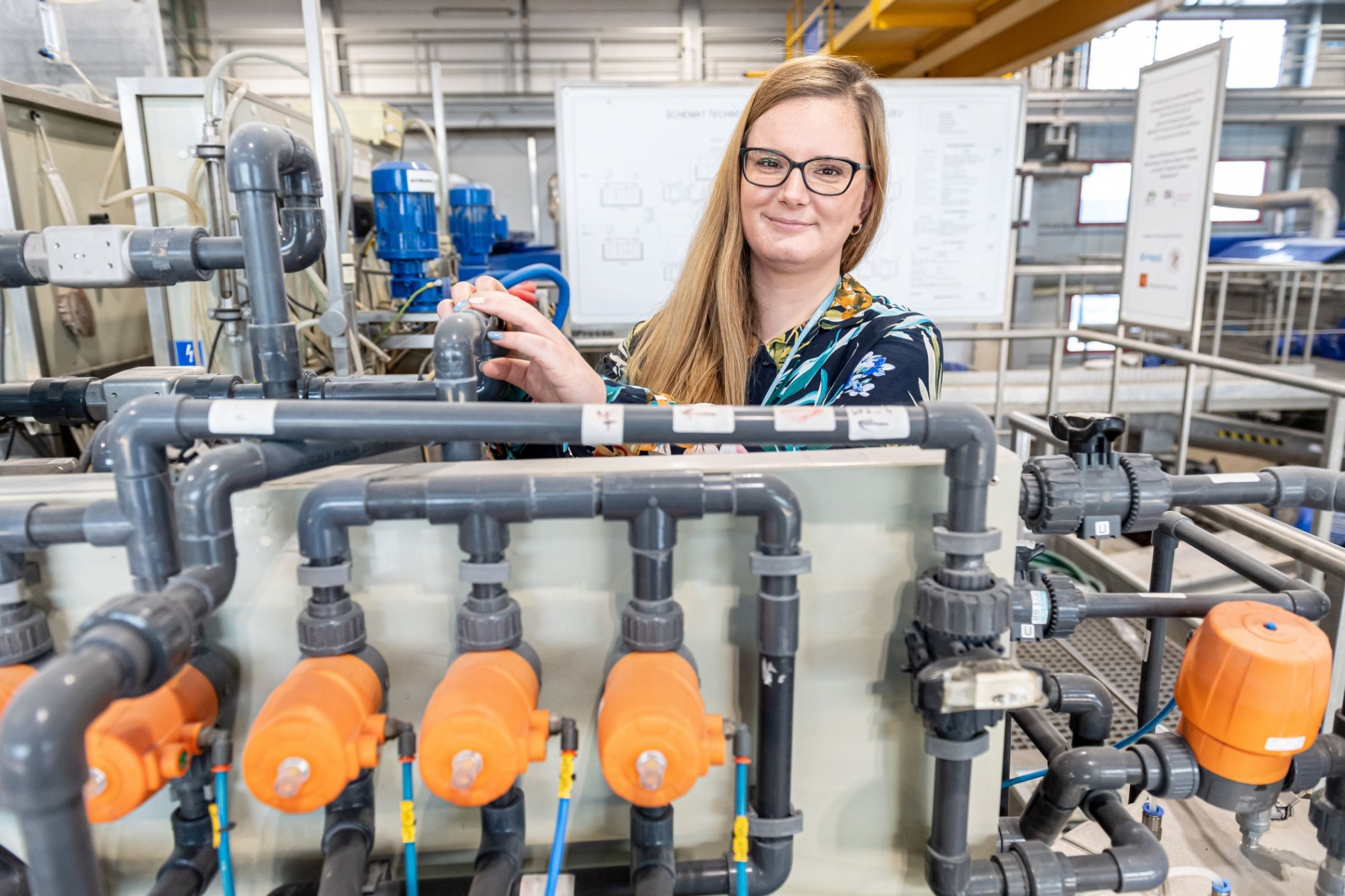

The project named "Towards a circular economy – technologies for the recovery of water and raw materials from treated wastewater" is presented by Daria Podstawczyk, PhD, Eng. from the Department of Process Engineering and Polymer and Carbon Materials Technology at the Faculty of Chemistry. The team she leads is working on the application of the membrane technology to use the waste stream for utility purposes.

Iwona Szajner: How did the idea for the research come about?

Daria Podstawczyk, PhD, Eng.: Water is becoming scarce worldwide; in Poland, too, surface water levels drop dramatically during periods of drought. We, therefore, face a huge challenge, which is finding an alternative source of clean water. So, by reusing treated wastewater, much of which is channelled into rivers, it’s possible to close the water cycle in line with the circular economy concept.

For many years, we have been cooperating with MPWiK’s New Technologies Centre in Wrocław and the team of Kamil Janiak, PhD, Eng. from the Faculty of Environmental Engineering at Wrocław University of Science and Technology. Together we decided to find a solution that would allow reusing treated wastewater.

And what happens now to treated wastewater?

It’s pumped into rivers or used, but without additional treatment, as process water in wastewater treatment plants, e.g. in sludge dryers. We want to develop an integrated system for the reuse of water and raw materials from treated wastewater in line with the principles of the circular economy.

So, this is the so-called third stage of wastewater treatment?

Exactly. The reclaimed water is primarily intended to replace treated wastewater as the cooling agent in the sludge dryer so as to eliminate the problem of fouling of the installation. What’s more, we’ve found a way to manage each stream generated during the processing of treated wastewater so that it is a waste-free technology. Other important elements of our project are monitoring micropollutants, the process of removing them, and improving the quality of treated wastewater.

Your research uses the membrane technology. Can you explain what it is?

I’ll try to make it more or less understandable (laughs). We use pressurised membrane processes which include microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Membrane separation uses membrane filters, which can be compared to sieves, but with slightly smaller (i.e. the micro- and nano-scale) pores. The membranes separate components of different size/molecular weight depending on the pore size. Depending on your needs, membrane processes can make it possible for you to purify, concentrate, or fractionate your raw material.

Membrane techniques have found applications in areas such as industrial and municipal wastewater processing and water treatment processes, mainly due to their high efficiency concerning the separated components, the lack of need for additional chemicals, low energy consumption, the possibility of performing continuous separation, and easy technology scaling under the so-called modular system.

So how does your approach to using this technique differ?

So far, membrane technologies have mainly been applied in the recovery of drinking water from treated wastewater, without the management of waste streams. Our project involves both the production of water of varying quality and the recycling of associated streams. In Poland, we lack the implementation of such a technological solution at existing wastewater treatment plants.

Are you preparing the technology for a specific treatment plant?

As far as the project goes, we’re using the research infrastructure for bench-scale membrane pressure separation owned by Wrocław’s Wastewater Treatment Plant. We were therefore able to bypass the testbed design and construction stage. We immediately kicked off the experiments. The membrane technology isn’t complicated, but expensive because of the installation. Membranes and membrane modules are relatively expensive, but thanks to their said simplicity, high performance, and the fact that they can be regenerated quickly and easily, investment costs can be recouped quickly. Our project is expected to end with the implementation of specific solutions at the Janówek facility, one of the largest in Poland. It’s also about reducing the consumption of water for the plant's own needs, which entails significant savings of operational costs. We hope that our solution will be a good example for other facilities, not only in Poland.

What raw materials can you obtain with these membrane “sieves”?

Each stage of wastewater treatment results in water of different quality and therefore fit for a different use, e.g. as process water, irrigation water for public greenery and fields, groundwater and, after disinfection, even drinking water, and high-purity water. We can recover elements such as magnesium, calcium, and phosphorus from the waste stream. They’re usually recovered through concentration on membranes and in precipitation reactions – in the form of calcium and magnesium phosphate salts. Such reactions can precipitate, for example, struvite, hydroxyapatite, and gypsum, which are substances used in agriculture as fertilisers, and also in medicine and the food industry. We can see potential where others see only waste. So, by using side streams, we give them a new life. To date, we’ve developed two innovative ways of preparing and making use of waste streams, which have been filed for patent protection.

*** The project is funded by the National Centre for Research and Development and the European Union under the Intelligent Development Programme 2014-2020. The project leader is MPWiK S.A. in Wrocław, with Wrocław University of Science and Technology acting as a partner. Started in February 2020, the project is planned to be completed in April 2022. Young researchers and students from the Faculty of Chemistry and Environmental Engineering are involved in the project, which also includes the development of a doctoral thesis and master's and engineering theses.

Our site uses cookies. By continuing to browse the site you agree to our use of cookies in accordance with current browser settings. You can change at any time.