YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 04.05.2022 Category: general news, science/research/innovation

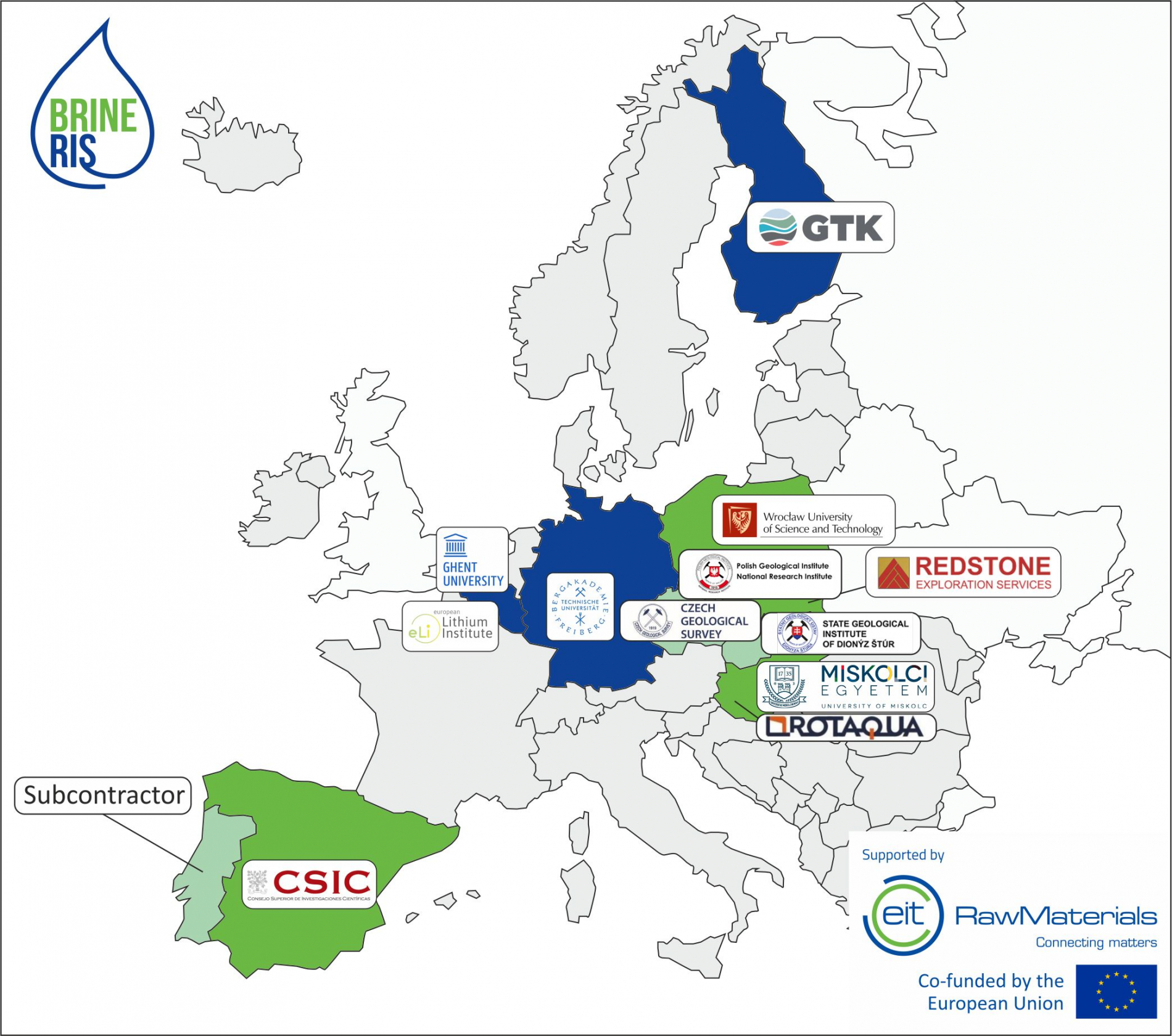

Scientists from several academic centres and research institutions have joined forces with industrial partners to test the feasibility of profitably extracting valuable metals – such as lithium – from selected groundwaters. Nine European partners are launching a project consisting in brine analyses and studies in Poland, Hungary, the Czech Republic, Slovakia, Spain, and Portugal. The joint activities are led by Wrocław University of Science and Technology.

The BrineRIS* project is led by Magdalena Worsa-Kozak, PhD from the Faculty of Geoengineering, Mining, and Geology, together with other scientists from the Department of Mining, the Department of Geodesy and Geoinformatics and researchers from the Faculty of Chemistry. They work with partners from Poland, Belgium, Finland, Hungary, Germany, and Spain.

Together, they intend to gather available information on the potential of brines that occur in selected six countries included in the so-called EIT Regional Innovation Scheme (EIT RIS), i.e. Poland, Hungary, the Czech Republic, Slovakia, Spain, and Portugal. But that's not all, as they will also carry out analyses of selected prospective 12 sources for extraction of metals from the brines using three technologies under development.

With a budget of 1.7 million EUR, the project is financed by EU funds under the KAVA 8 EIT Raw Materials programme.

Lithium is one of the metals of great importance for industries such as the rapidly growing electric car sector. It is used for the manufacture of automotive batteries, specifically to produce lithium-ion batteries with long life and short charging times.

Lithium is one of the metals of great importance for industries such as the rapidly growing electric car sector. It is used for the manufacture of automotive batteries, specifically to produce lithium-ion batteries with long life and short charging times.

Experts estimate that by the end of the decade, the demand for lithium, which is already very high, will have increased by up to five times.

Much of the lithium produced today is extracted from brine reservoirs known as salars, found in the high altitude areas of Bolivia, Argentina, and Chile. The element-rich waters must first be pumped into several large evaporation ponds, where the water evaporates under high temperatures for several months. As a result of processes including extraction and filtration, lithium carbonate is produced – a stable white powder that can be transformed into certain industrial salts and chemicals or processed into pure lithium metal.

However, this production process has a major impact on the environment – through the huge areas taken up, the irreversible use of huge quantities of water, and the lowering of groundwater levels due to the pumping of brine, among other things. The chemicals used in the evaporative method are also a problem. Weather issues are also a hindrance because if temperatures are not high enough, the water in evaporation ponds does not evaporate.

Therefore, technologies of so-called direct lithium extraction, which increase the efficiency of the extraction process and make it independent of the weather, are being developed in many centres all over the world. These methods use electricity and various chemical processes to isolate and extract concentrated lithium. Here, however, there is the issue of electricity prices, which affects the profitability of production.

Therefore, another potential solution to the problem could be to extract lithium from geothermal brines while using geothermal energy to generate green electricity.

Therefore, another potential solution to the problem could be to extract lithium from geothermal brines while using geothermal energy to generate green electricity.

– Such pilot installations are already being tested in several parts of the world, producing lithium hydroxide or lithium carbonate” – says Magdalena Worsa-Kozak, PhD. – Our task is to verify the potential for such investments in six RIS countries, which are known to have brine resources. So, we will create a database of very valuable information and analyses for investors who might be interested in developing such installations in Poland, Hungary, the Czech Republic, Slovakia, Spain, or Portugal. As the European Union is currently supporting investments in areas such as the use of geothermal sources, the results of our project may result in substantial investments supported by European funds.

The project involves several simultaneous action paths. Its participants intend, among other things, to collect all available information on the occurrence of brines and their composition – especially in terms of their lithium, strontium, and barium content.

The project involves several simultaneous action paths. Its participants intend, among other things, to collect all available information on the occurrence of brines and their composition – especially in terms of their lithium, strontium, and barium content.

– Currently, this data is very scattered – explains the researcher. – There is no single place where an interested entrepreneur can view a cross-section of such information. In addition, some of the research into the chemical composition of brines, for example, was carried out as part of scientific or investment projects related to other topics, and this data has never been analysed in terms of elemental recovery or made public in any form.

The second path will be to analyse the potential of selected brines with three direct lithium extraction technologies. Electrochemical methods of recovery will be analysed by Ghent University, the adsorption method – by the Geological Survey of Finland ( GTK ), and solvent extraction – by the GTK in cooperation with Prof. Leszek Rycerz and Katarzyna Ochromowicz, PhD, Eng from Wrocław Tech. In addition, selected brines will be tested in Germany by the project's industrial support partner Vulcan Energie Ressourcen.

– Our task is to test these technologies for specific brines and determine that for these sources, a given technology will allow the recovery of certain quantities of elements under set boundary conditions – explains the project leader.

– Our task is to test these technologies for specific brines and determine that for these sources, a given technology will allow the recovery of certain quantities of elements under set boundary conditions – explains the project leader.

From each brine selected for detailed study, the scientists will need to take both small samples for quick and simple chemical analyses on-site as well as large volumes of water (about 150-200 l), which they will send to Belgium, Finland, and Germany – for more advanced analyses.

They will consider, among other things, the content of metals in a given source, but also its temperature, stability, and yield – as all these factors are important in assessing the profitability of extracting metals from brine.

– We’ll also be analysing those brines which have lower temperatures, e.g. around 40 or 60 degrees C., therefore being unsuitable for electricity production – says Dr Worsa-Kozak. – Instead, they may be suitable for heat production, which is why the researchers at TU Freiberg will classify those brines from which heat could be used to improve the process itself, for example, to heat cooler water and improve the efficiency of the technologies being tested, thus reducing the costs.

As part of the project, also a website will be created for entities interested in investing in brine installations – providing access to information and analyses conducted under the BrineRIS initiative.

Also planned are open workshops on the potential of geothermal brines, study visits by scientists, and a summer school for students in Karlsruhe organised by Vulcan Energie Ressourcen. The project will also result in engineering and master's theses.

*The BrineRIS project means “Brines of RIS countries as a source of CRM and energy supply”. Partners involved in the project include Wrocław University of Science and Technology (as a leader), CSIC – The Spanish National Research Council, The University of Miskolc, Ghent University, TUBA Freiberg, European Lithium Institute eLi, GTK – The Geological Survey of Finland and Redstone Exploration Services.

Our site uses cookies. By continuing to browse the site you agree to our use of cookies in accordance with current browser settings. You can change at any time.