YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 26.03.2020 Category: international cooperation, science/research/innovation

Researchers from Wrocław University of Science and Technology and the University of Witwatersrand in Johannesburg are working on a numerical model of a power boiler which will show what changes about its operation when more energy from renewable sources is fed into the grid and coal-fired power plants have to work with less efficiency. The researchers are also experimenting with a more effective reduction of nitrogen oxides and mercury in power units’ combustion processes.

Researchers from Wrocław University of Science and Technology and the University of Witwatersrand in Johannesburg are working on a numerical model of a power boiler which will show what changes about its operation when more energy from renewable sources is fed into the grid and coal-fired power plants have to work with less efficiency. The researchers are also experimenting with a more effective reduction of nitrogen oxides and mercury in power units’ combustion processes.

Although undoubtedly coal combustion is still the main source of electricity in our country, the number of solutions using renewable sources (such as photovoltaic panels or wind turbines) has been growing in recent years. It is assumed that by 2030, Poland, following the EU climate and energy policy, will have increased the share of renewable energy sources in the county’s final energy production volume to 21% (from 2021, coal-fired power plants will also be obliged to meet new strict standards of emissions to the environment).

Each year, more and more energy from RES is fed into the power grid, and it is expected to continue, also outside Poland. As we are bound by international agreements on energy import and export, our system is also affected by what is happening in the neighbouring countries. In the meantime, our neighbours in the West decided that they were going to give up on traditional energy production as soon as possible. By 2038, Germans want to phase out all of their coal-fired power plants (as well as CHP plants) one by one.

The production of energy using RES is not without influence on the coal-based power industry. This is due to their - as experts call it - poor controllability. When we are enjoying many sunny days or strong wind has been blowing for a long time, a lot of energy goes into the grid, causing traditional power plants to reduce production - sometimes quite considerably, even below the minimum technical level of power boilers.

Coal-fired power plants must be complementary to renewable sources and respond to rapid changes in their output, which means very specific problems faced by conventional power plants, bound to become more serious with the growing popularity of RES.

Coal-fired power plants must be complementary to renewable sources and respond to rapid changes in their output, which means very specific problems faced by conventional power plants, bound to become more serious with the growing popularity of RES.

- Each device being a component of a power unit has been designed to operate with the highest efficiency for precisely defined nominal parameters. Nobody assumed such flexibility of these solutions, because years ago it was unnecessary. A power unit was supposed to work within a certain power range, explains Norbert Modinski, PhD, DSc, University Professor from the Department of Mechanical Engineering, Machinery, Devices, and Power Engineering Processes at the Department of Mechanical And Power Engineering Department. - At present, new requirements are being put in effect concerning units deviating from the original technical assumptions, which may result in the deterioration of power unit elements’ working conditions.

In times of high supply of energy from RES, the easiest thing to do seems to be to shut down the power unit. However, the procedure and subsequent start-up mean many considerable difficulties for the unit operator.

- A coal-fired unit is a huge and complicated installation the size of our university’s main building - vividly explains Krzysztof Czajka, PhD, DSc, Eng, University Professor, also from the Department of Mechanical Engineering, Machinery, Devices, and Power Engineering Processes. - So it is not a device such as a microwave, for instance, in which you can freely set the power level according to your needs, and when you don’t need it, pull the plug out. Turning it off and then starting up and having it feed the grid takes a few hours and is very burdensome. It requires several actions, during which something can always go wrong.

- And on top of that, during the start-up, pollution is emitted - adds Professor Modliński. - This is because all the installations responsible for flue gas cleaning are not yet working under their nominal operating conditions. Analyses often show that it is much better not to turn such a boiler off, but to make it work at a lowered minimum technical capacity. This situation is analogous in several respects to an old car left with its engine running when you jump out of it for a short while to run a quick errand, because if you turn it off, it may cost you a lot of time and nerves to restart it.

However, what will happen when the boiler works with decreased efficiency - also, more and more often and for longer? How will this affect its components? This will be looked at in great detail by researchers from Wrocław University of Science and Technology and the University of Witwatersrand in Johannesburg. The team of Professor Modliński’s collaborators (Professor Halina Pawlak-Kruczek, Professor Krzysztof Czajka, Anna Kisiel-Czajka, PhD. Eng., and Michał Ostrycharczyk, PhD, Eng. - all from the same department) together with scientists from the Republic of South Africa intend to develop numerical models of the power boiler. Employing computer simulation, they want to determine the impact of its operation at a lower (than before) technical minimum capacity on the installations that it comprises.

However, what will happen when the boiler works with decreased efficiency - also, more and more often and for longer? How will this affect its components? This will be looked at in great detail by researchers from Wrocław University of Science and Technology and the University of Witwatersrand in Johannesburg. The team of Professor Modliński’s collaborators (Professor Halina Pawlak-Kruczek, Professor Krzysztof Czajka, Anna Kisiel-Czajka, PhD. Eng., and Michał Ostrycharczyk, PhD, Eng. - all from the same department) together with scientists from the Republic of South Africa intend to develop numerical models of the power boiler. Employing computer simulation, they want to determine the impact of its operation at a lower (than before) technical minimum capacity on the installations that it comprises.

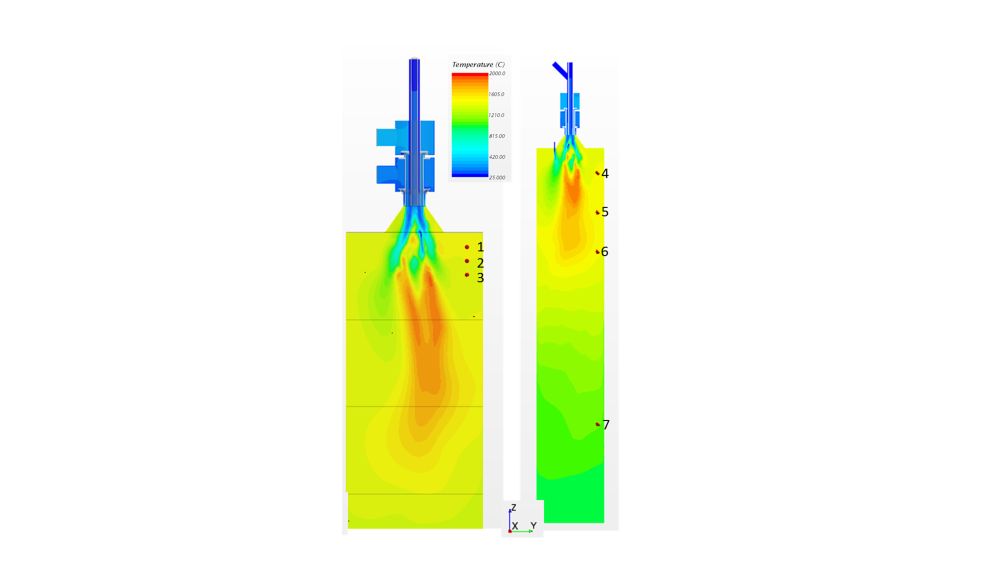

- This will be, to a great degree, the engineer’s tool - emphasises Professor Modliński. - Its first part will simulate the combustion process itself, as well as its stability and quality at low boiler loads. By lowering the power output of the power unit or just the boiler, we can expect problems, e.g. with air management, and as a result, the burners in the boilers will not operate to a capacity expected by the operator. The second part will be a simulation of the entire boiler or power unit without a detailed analysis of the combustion process, which will make it possible to look at individual boiler components and what they experience while working at a low load. We will be able to see, for example, that the temperature of the flue gas at the catalyst inlet is below the threshold at which it can operate, and the operator will have to find a solution to this problem. It may also turn out that the parameters of the steam feeding the turbine are below the limit point. The simulation will, therefore, indicate potential operating problems.

The first part of the simulation will be based on research that the scientists will carry out using one of the most exceptional research installations in the world. They will look at the phenomenon of ignition and propagation (i.e. spread) of the flame using a single low-emission burner (of the impressive 1 MW) in a pilot installation in Eskom Research Test and Development (one of only a few such large research installations of this type worldwide).

The first part of the simulation will be based on research that the scientists will carry out using one of the most exceptional research installations in the world. They will look at the phenomenon of ignition and propagation (i.e. spread) of the flame using a single low-emission burner (of the impressive 1 MW) in a pilot installation in Eskom Research Test and Development (one of only a few such large research installations of this type worldwide).

They will test the burner operation for different fuels, excess air coefficients, fuel and air streams, and the degree of turbulence of the so-called secondary and tertiary air (i.e. the pulverised-air mixture used in pulverised energy boilers). This will enable them to determine the requirements for the boiler and mill system control, which will allow optimal operation in all conditions.

The use of the installation is possible thanks to the close cooperation between the University of Witwatersrand and the South African company Eskom, which initiated the opening of an institute focusing on research in the power industry at this university and is financing its activities. Eskom produces, transmits, and distributes electricity. It is the largest producer of electricity in all of Africa and one of the top ten in terms of capacity and sales worldwide.

- Thanks to this, we not only have the opportunity to carry out tests in a unique installation, but we can also benefit from the experience of specialists working in a company being of the biggest players in this industry - emphasises Professor Modliński.

The second part of the numerical model under development will involve multi-burner tests conducted in the HECLE boiler. The acronym stands for Highly Efficient, High Capacity, Low Emission and denominates high-performance, low-emission power units featuring a high power output, hundreds of which have been put into operation in recent years around the world - including Poland and South Africa. Research conducted in a boiler of this kind will focus on evaluating the flame behaviour in the combustion chamber as a function of the settings and operating conditions of the main components of the combustion system - such as fan efficiency, air heater efficiency, as well as the mill system and its configuration. For the time being, it is known for sure that the analyses will be carried out using a boiler in South Africa, but the scientists are in talks with a Polish company which has also built a HECLE and want to interest it in cooperation in this field.

Thanks to all these analyses, the thermodynamic model of the boiler will make it possible to determine a safe operation regime of the boiler at a lowered technical minimum. By using it, the researchers will also be able to indicate potential operating ranges without modifying the pressure part and combustion system, with minor changes in the control system or significant modifications of some components.

The development of a numerical model is only part of the tasks that the researchers have set for themselves within the joint project, as experimental research is also planned.

The development of a numerical model is only part of the tasks that the researchers have set for themselves within the joint project, as experimental research is also planned.

The first piece of research involves a search for methods to increase the effectiveness of nitrogen oxides reduction (at a low flue gas temperature) in the SCR installation (i.e. selective catalytic reduction), which is used in a boiler to reduce nitrogen oxides to water vapour and non-toxic nitrogen.

- As we’ve already mentioned, all boiler components were designed with specific parameters in mind. Also the flue gas cleaning systems - says Professor Krzysztof Czajka. - In the denitrification installations, an agent, such as ammonia, is applied to reduce pollution. Its amount is accurately calculated in correlation to the amount of flue gas that goes to the boiler in a given unit of time, as well as to the temperature and specific chemical composition of these gases. At a different boiler load, these parameters change, so if there is less flue gas in the boiler and you do nothing about it, the ammonia starts penetrating into the atmosphere, which means that instead of cleaning the flue gases we will pollute them even more.

Therefore, the participants of the project intend to find a material that will act as a catalyst for the reduction of nitrogen oxides and while adsorbing (which is like assimilating, to put it very simply) unreacted ammonia, so that it does not get into the atmosphere.

Therefore, the participants of the project intend to find a material that will act as a catalyst for the reduction of nitrogen oxides and while adsorbing (which is like assimilating, to put it very simply) unreacted ammonia, so that it does not get into the atmosphere.

- This material must be functional in the so-called wide temperature window - emphasises Anna Kisiela-Czajka, PhD, who is the project team member responsible for this task. - With a variable load of the boiler, the temperature and composition of the flue gas, among other things, will change, too, so we have to choose a catalyst that will perform well in various conditions.

The scientists will build a laboratory workstation simulating conditions in the power unit. There, flue gases will be passed through a deposit acting as a catalyst.

- The most common commercially used catalysts are metallic support catalysts - says Kisiela-Czajka, PhD. - We, on the other hand, will propose carbon materials, which can work effectively at much lower temperatures. The research conducted so far, in countries including Germany, has already proved the effectiveness of coal materials in boiler flue gas purification, both from nitrogen oxides and sulphur dioxide. Having said that, our research goes one step further as we intend to apply materials that have been considered as waste.

So far, the purification plants have been using active carbons produced in specialised plants. The researchers from WUST, on the other hand, want to use much cheaper materials, i.e. remnants of the fossil fuel combustion process. Waste produced in refineries or during the recycling of used tyres can be used as well.

- So these will be post-process waste materials, characterised by a significant concentration of elemental carbon - emphasises Kisiela-Czajka, PhD. - The main aspect influencing the efficiency of pollutant reduction is the porous and chemical structure of these materials. After researching source materials, we also plan to develop a method for modifying their physicochemical properties, e.g. by increasing the available surface area or changing their chemical properties to intensify their flue gas cleaning capacity.

The analyses carried out so far by Kisieli-Czajka, PhD and Professor Czajka related to the use of carbon materials to remove pollutants from the atmosphere were recognised at the 7th edition of the Academic Entrepreneurship Competition, where their research was awarded the title of Academic Leader of Innovation.

The analyses carried out so far by Kisieli-Czajka, PhD and Professor Czajka related to the use of carbon materials to remove pollutants from the atmosphere were recognised at the 7th edition of the Academic Entrepreneurship Competition, where their research was awarded the title of Academic Leader of Innovation.

Part of the project will also include research into capturing mercury from flue gases using catalysts, to be carried out by Professor Halina Pawlak-Kruczek and Michał Ostrycharczyk, PhD.

- It’s necessary to check whether, when changing the temperature profile on the flue gas way in the boiler and subsequently during flue gas cleaning, mercury is not emitted into the atmosphere in the worst possible, elementary, form - explains Michał Ostrycharczyk, PhD. - This form isn’t treated in existing power plant installations and doesn’t bind in any materials, in contrast to the oxidised form, which is formed when combined with compounds such as chlorine or bromine, and the solid form found in ash. As is the case with the purification of nitrogen oxides, it’s necessary to select a catalyst that is capable of working at lower temperatures and with a variable flue gas composition. The catalyst could be part of an SCR installation, i.e. denitrification, or could be located as the last point of the installation where the temperature is between 150 and 300 degrees Celsius.

Michał Ostrycharczyk, PhD takes into account various metal oxides such as ruthenium and titanium oxide, as well as manganese.

As the researcher explains, so far no special mercury capture installations have been installed in power units, as this was not required by law (an electrostatic precipitator and flue gas desulphurisation installation can capture about 75% of mercury from flue gases) - as the emission level of this pollutant ranged between 5-20 µg/m3 (or a few millionths) grams. The mercury emission standard currently being introduced in the European Union for operating power plants is a maximum of approx 10 µg/m3 (depends on power plant type).

To comply with this standard, some power units use either activated carbon or appropriate chlorine content in the flue gas, which results in the oxidation of the mercury and easier discharge of the mercury from the flue gas.

- Some manufacturers boast that they offer catalytic inserts for SCR, which also reduce mercury, but are unable to guarantee specific reduction levels - adds Professor Modliński. - This is due to monitoring difficulties. Part of the reduction occurs directly in the catalyst and another part is reduced in a desulphurisation plant, which is shared between several units. Therefore, additional analyses are necessary, which will determine very precisely the reduction level for a particular unit.

The research conducted by WUST and the University of Witwatersrand is possible under the project entitled “Environomical Impact of Enhanced Coal Power Plant Operating Flexibility”. The funding was provided by a grant being the prize in a competition for joint Polish-South African research projects. The initiative was announced jointly by the National Centre for Research and Development and the National Research Foundation of South Africa. The project carried out by our university and the foreign partner started in March 2019 and will take three years to complete.

The research conducted by WUST and the University of Witwatersrand is possible under the project entitled “Environomical Impact of Enhanced Coal Power Plant Operating Flexibility”. The funding was provided by a grant being the prize in a competition for joint Polish-South African research projects. The initiative was announced jointly by the National Centre for Research and Development and the National Research Foundation of South Africa. The project carried out by our university and the foreign partner started in March 2019 and will take three years to complete.

It is WUST’s second major scientific project undertaken in cooperation with Wits thanks to this programme. The first, finished last year, concerned the development of a forecasting procedure for evaluating the coal dust combustion process. It was also headed by Professor Norbert Modliński.

- The cooperation between WUST and Wits wouldn’t be possible if it hadn’t been for the involvement of Professor Louis Jestin, who was a long-term technical director of the French branch of EDF Polska and the founder of a consortium of the university and EDF, whose purpose was research for the power industry in Poland - says Professor Modliński. - At that time, the head of that consortium was Professor Maciej Chorowski from our Faculty. Professor Jestin left Poland and it was South Africa where he headed. There, he conducted research and development activities of a similar nature and supported both cooperation projects.

The similarities between the Polish and South African energy sectors result in proposals to increase the scale of cooperation between WUST and Wits - to exchange experience and knowledge, also after the completion of the research project.

Lucyna Róg

Our site uses cookies. By continuing to browse the site you agree to our use of cookies in accordance with current browser settings. You can change at any time.