YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 26.06.2025 Category: science/research/innovation

OrthoNail, a smart implant for lengthening long bones, is one of the exhibits presented in the Polish Pavilion at the World Expo in Osaka. The invention is being developed by researchers from the Faculty of Mechanical Engineering at Wrocław University of Science and Technology as part of the Orthoget company’s activity.

Open to visitors until mid-October, the World Expo exhibition was organised by the Japanese on the artificial island of Yumeshima, covering an area of over 150 hectares, and divided into the World of Pavilions, the World of Water, and the World of Greenery. The organisers estimate that within six months of opening, the exhibition will be visited by over 28 million people, including 3.5 million foreign visitors.

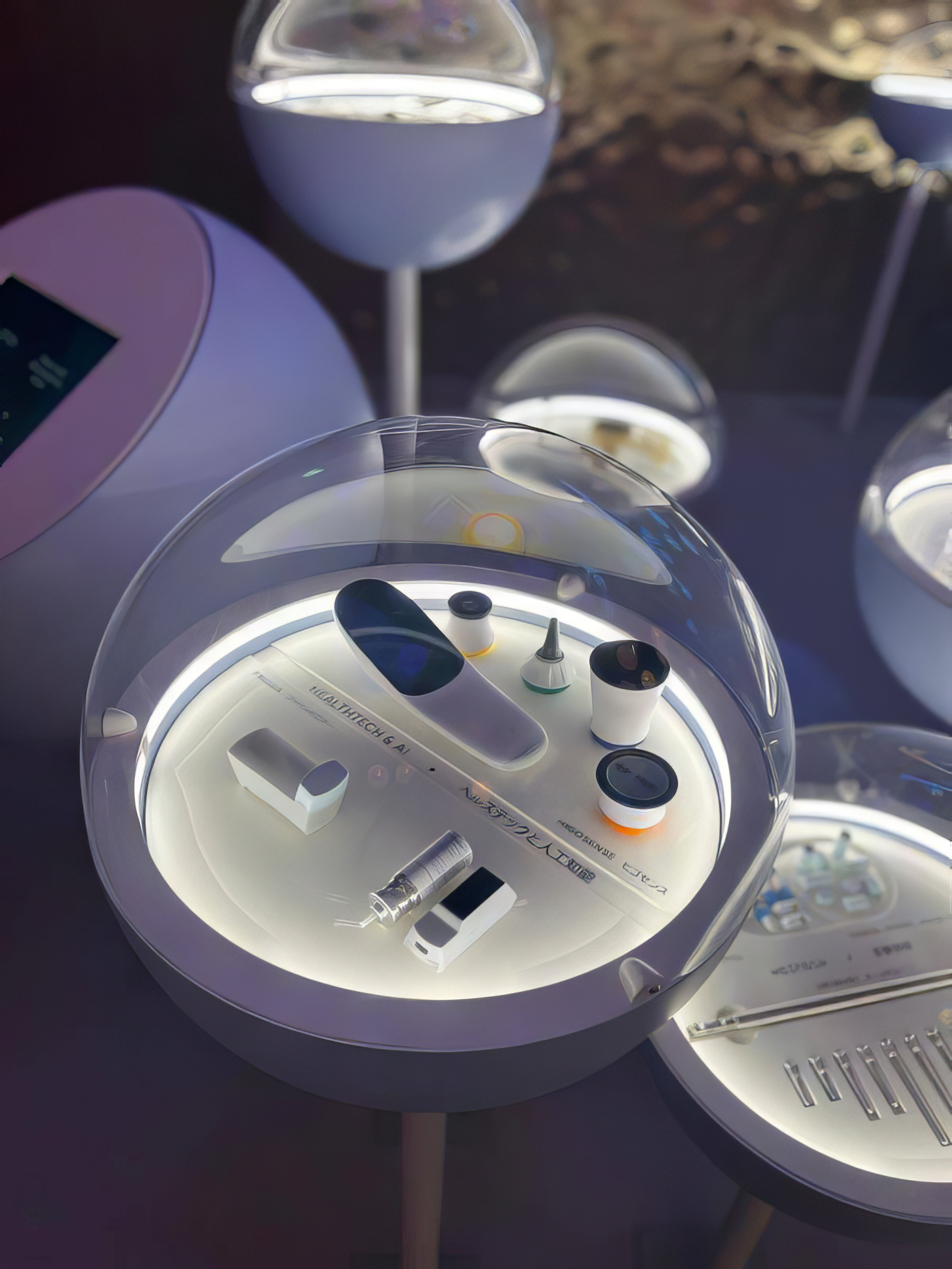

160 countries are showcasing their achievements in Osaka. One of the permanent exhibition areas in the Polish Pavilion, called “Plantation of Ideas”, features ideas and groundbreaking innovations from six industries that are strategic for us: agri-food, medical and pharmaceutical sector, cosmetics, green technologies, gaming, and IT/FinTech.

160 countries are showcasing their achievements in Osaka. One of the permanent exhibition areas in the Polish Pavilion, called “Plantation of Ideas”, features ideas and groundbreaking innovations from six industries that are strategic for us: agri-food, medical and pharmaceutical sector, cosmetics, green technologies, gaming, and IT/FinTech.

Among the medical inventions that we are showcasing to the whole world is an implant that researchers from the Faculty of Mechanical Engineering at Wrocław University of Science and Technology have been working on for several years as part of the operations of the Orthoget company. The solution is currently undergoing clinical trials.

A solution to be applied if the bones of the limbs are of different lengths

The name of the solution, an intramedullary implant for active lengthening of long bones, is Orthonail. This medical product was originally designed for people with limb asymmetry, i.e. patients whose one leg is at least 2 cm shorter than the other.

Asymmetry can be congenital, but it can also be the result of an accident or fracture (even multiple simple fractures of the same bone can result in its shortening).

According to statistics, in our country alone, 2% of the population has clinically significant limb length discrepancy (LLD), and 1 in 1,000 people suffer from severe limb asymmetry.

This has serious consequences – from balance disorders, through spinal curvature and vertebral deformities, to various types of degenerative changes. Psychological issues are also important, i.e. the stress associated with living with a shorter limb.

This has serious consequences – from balance disorders, through spinal curvature and vertebral deformities, to various types of degenerative changes. Psychological issues are also important, i.e. the stress associated with living with a shorter limb.

Currently, many techniques are used to lengthen limbs. Among the methods paid for by our country’s public healthcare system is the Ilizarov method (implemented in the 1950s). It involves the use of an external device with rings connected to rods that pass through the tissues and the lengthened bone. The technique is inexpensive, but also painful, and it requires the patient to remain immobile for about three months.

Also used are implants stimulated externally by an electrical signal, but these also require the use of crutches or a wheelchair during the implant elongation (and bone fusion) period.

Implants that use a rotating external magnet to stimulate the magnet inside the implant to gradually lengthen are also popular, but this solution, known for its costliness, is mainly offered by private clinics.

– That’s why we’ve developed a solution that will better meet patients’ needs at a significantly lower cost – says Assoc. Prof. Dominika Grygier, PhD, DSc, Eng. The researcher, specialising in materials science, biomaterials, and coatings, works at the Faculty of Mechanical Engineering at Wrocław University of Science and Technology and heads a project carried out in cooperation with the Wrocław-based company Orthoget.

A team of researchers from several departments of the Faculty of Mechanical Engineering is working on the bone lengthening implant project. The team comprises, apart from Prof. Grygier, Piotr Kowalewski, PhD, DSc, Eng., Mariusz Opałka, PhD, Eng., Jakub Słowiński, PhD, Eng., and Dariusz Pyka, PhD, Eng.

The Orthonail implant, an intramedullary nail made of titanium alloys and ferrite-free materials, uses a hybrid magneto-mechanical mechanism. In addition to the magnet, it houses a compressed spring which, when expanded, releases the energy accumulated in the implant structure. An exciter is used to stimulate the implant to elongate. Unlike other solutions available on the market, it does not use permanent magnets, but a system based on coils that create a magnetic field and cause the magnet in the implant to move. The device is capable of lengthening the bone by up to 8.5 cm.

Professor Grygier Emphasises that Orthonail will not only be cheaper than other similar currently available solutions, but above all, it will enable the transfer of up to 80% of the patient's body weight to both legs.

What does that mean exactly? As soon as the implantation procedure has been completed, the patient can move around using crutches, which in many cases are no longer necessary after a few days, according to doctors whose patients are participating in the clinical trial programme for the implant. At present, such research is being conducted by a clinic in Warsaw.

– Our strength tests have shown that Orthonail implants can withstand loads of up to approximately three tonnes, which gives us a large safety buffer and allows patients to move around. Of course, we’re still working to confirm this in clinical trials, but the initial results already indicate that this is the case, emphasises Prof. Grygier.

Patients taking part in clinical trials also have access to a special app that allows them to track the progress of implant elongation and use rehabilitation exercises tailored to their needs. Also, doctors caring for patients log into the remote treatment progress monitoring system, which gives them insight into the current status of rehabilitation, changes in bone lengthening progress, and complete documentation of the patient's history.

“In addition to improving the quality of medical care, the solution enhances safety,” explains Prof. Grygier. “We all tend to be impatient during the treatment process. We want to achieve results as quickly as possible. The patient may be tempted to extend the implant more often or more than they should. This would mean, for example, tissue damage and interrupted bone regeneration, which would simply undo all the progress made. This is why the application and the system allow you to monitor the entire process on an ongoing basis and perform extension only during scheduled sessions, i.e. in specific time slots. It’s a bit like parental control on a phone. Of course, for the patient's benefit.”

After completing clinical trials, Orthoget will begin the process of obtaining CE certification for its implant, which will make it possible to launch it on the market. It also plans to conduct clinical trials in the US and ultimately sell its products not only in Europe, but also in the US and Asian countries.

“We can see considerable interest in our implant in the aesthetic medicine market as well,” says Prof. Grygier. “That surprised us, because we had no idea that there was such a high demand for solutions for people who are uncomfortable with their height but don’t want to undergo highly invasive procedures that would immobilise them for a long time.

More information about the Orthonail implant can be found on the company's website. In September, our researchers will be presenting their solution to visitors at Expo 2025 in Osaka.

Our site uses cookies. By continuing to browse the site you agree to our use of cookies in accordance with current browser settings. You can change at any time.