YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 14.03.2023 Category: general news, science/research/innovation

Our researchers are entering a collaboration with partners from Germany and Spain to investigate innovative materials for electronic and sensor-related applications based on copper and glass. To fund their project, they will use a grant from the National Centre for Science (NCS) as part of an m-ERA.NET 3 competition.

International projects funded by the M-ERA.NET 3 programme support research in the fields of materials science and engineering. International consortia comprising at least three research teams from at least two participating countries were eligible to apply for funding.

A total of 289 applications were submitted with 46 projects receiving funding that totalled 43.7 million EUR, including ten (a record number) projects from Poland. One of these will be carried out in collaboration with Wroclaw Tech researchers.

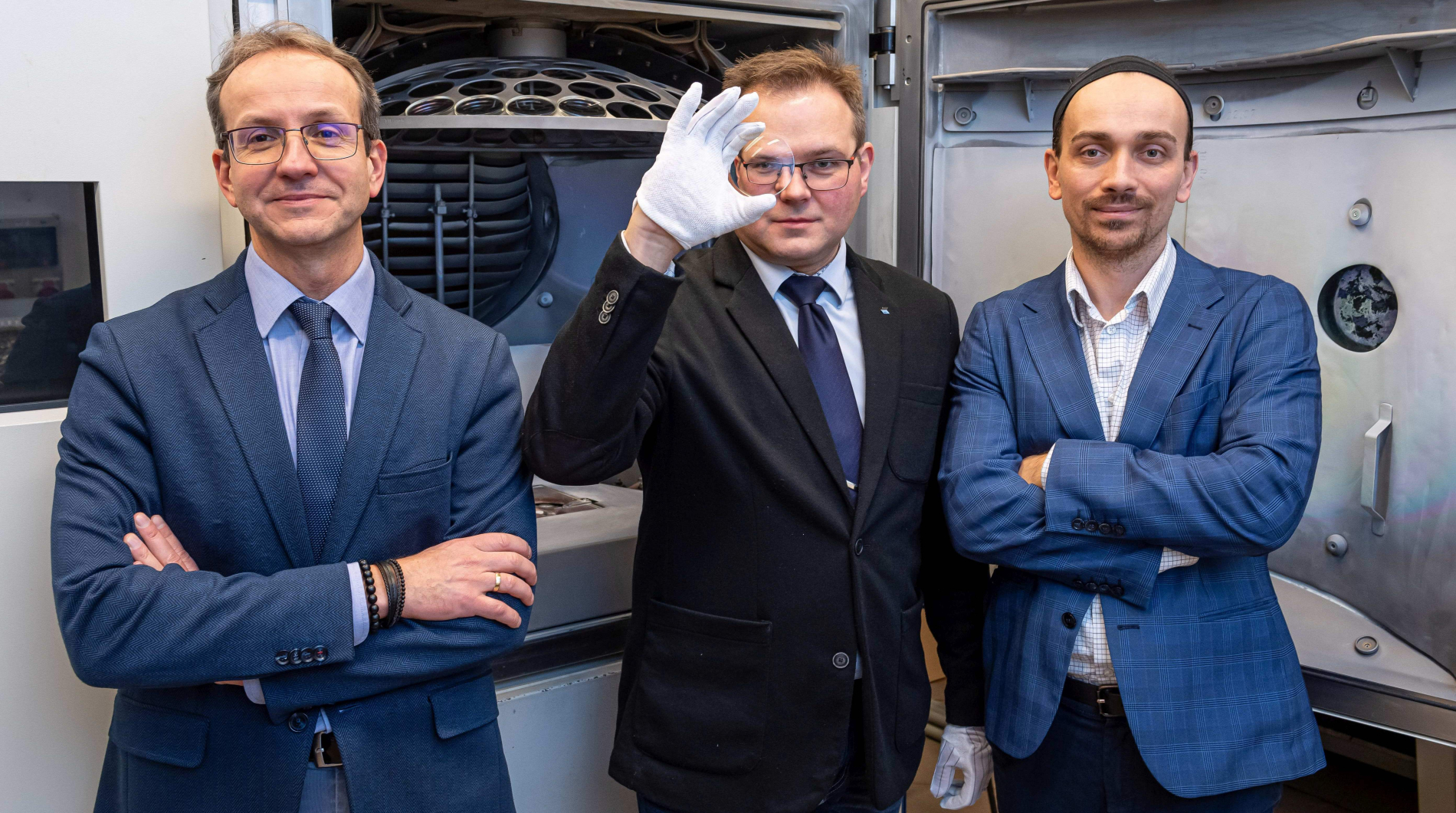

The COCO (Copper conductive lines with glass insulation by a melt extrusion process) project is coordinated by the Fraunhofer Institute for Machine Tools and Forming Technology IWU. The initiative involves representatives of the Spanish company MicruX Fluidic, S.L and researchers from Technische Universität Bergakademie Freiberg (Germany), as well as Wroclaw Tech’s Faculty of Electronics, Photonics, and Microsystems. Our team comprises Prof. Jarosław Domaradzki (Head), Professor of the University Robert Król, PhD, DSc, Eng., and Professor of the University Michal Mazur, PhD, DSc, Eng.

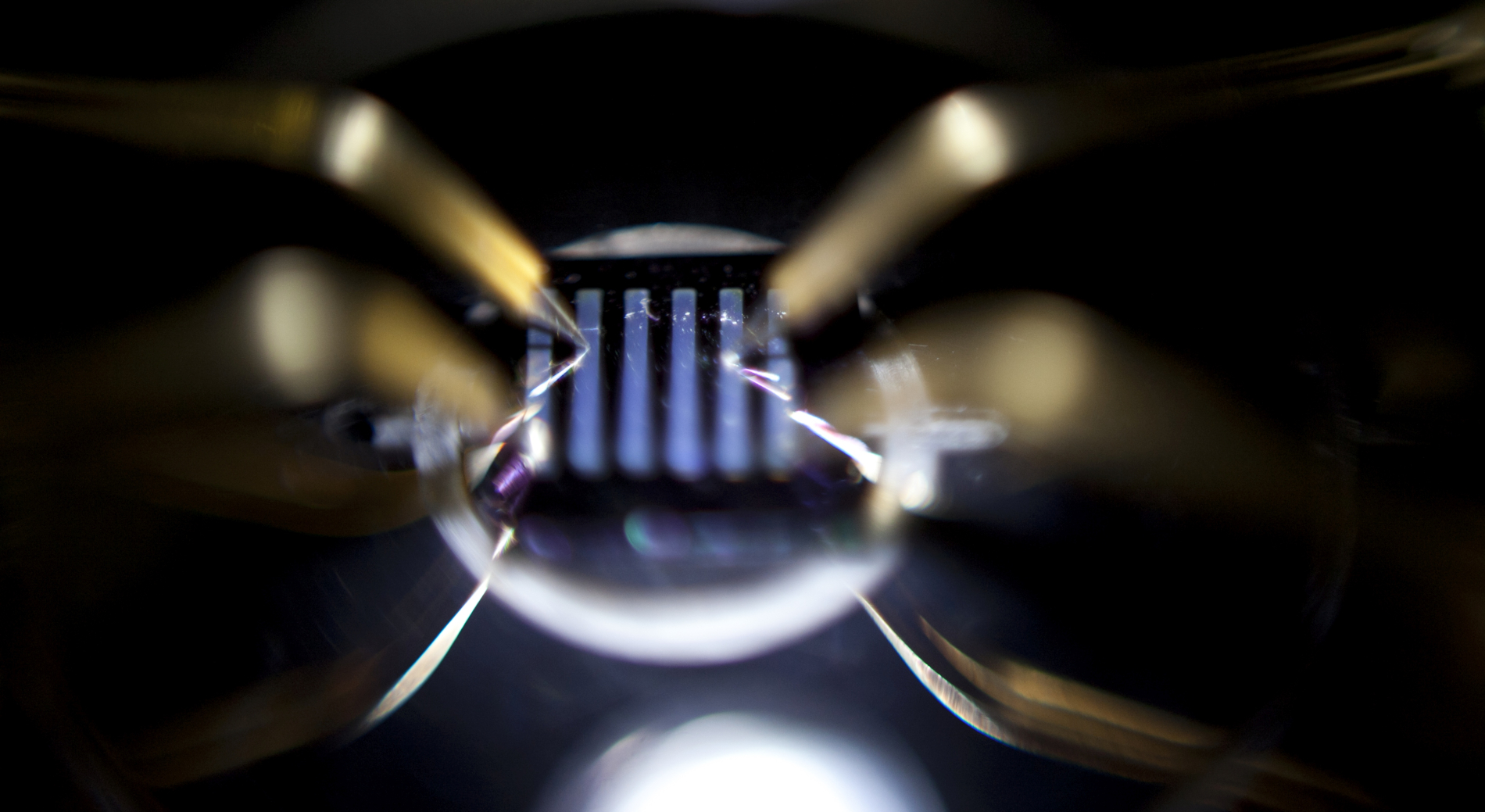

As a partnership, they will embark on an undertaking consisting in researching and developing concepts for innovative multifunctional materials with electronic and sensor applications in mind, based on copper as a highly conductive material and glass as a dielectric material. By using additive manufacturing (AM) techniques, it will be possible to miniaturise three-dimensional electrical and electronic components.

“Harnessing the properties offered by the copper-glass combination will improve existing electronic devices by enhancing their versatility and functionality, increasing their operating temperature range, and improving their chemical and mechanical stability,” says Prof. Jarosław Domaradzki from the Faculty of Electronics, Photonics, and Microsystems, head of the Polish team.

“Harnessing the properties offered by the copper-glass combination will improve existing electronic devices by enhancing their versatility and functionality, increasing their operating temperature range, and improving their chemical and mechanical stability,” says Prof. Jarosław Domaradzki from the Faculty of Electronics, Photonics, and Microsystems, head of the Polish team.

The use of AM technology, where the material is only applied at the desired place, will result in significantly less raw material being used, which also translates into less waste. Thus, the project will contribute to an increase in environmental awareness, including more efficient use of resources and energy.

“Our team will be tasked with performing material analyses and tests of the electrical properties of the manufactured copper-glass combinations and the copper electrodes themselves. One of the ultimate goals of the project is to develop a demonstrator and test it in an industrial environment. The latter task will be handled by an industrial partner from Spain,” explains Prof. Jarosław Domaradzki. “The manufactured components in the form of a glass substrate with fabricated copper electrodes will be tested in an electrochemical sensor structure designed for microfluidic applications,” adds the researcher.

The total value of the project amounts to over 1.4 million EUR.

Our site uses cookies. By continuing to browse the site you agree to our use of cookies in accordance with current browser settings. You can change at any time.